Illuminate™ software features at a glance

The Illuminate™ solution offers many unique features to provide additional valuable insights into your system performance.

Production and Quality Improvement

Performance Sustainability

Performance Analysis

Illuminate™ software continually analyzes all data produced and utilizes feedback to allow you to course-correct your manufacturing production and processes – all without manual intervention.

- OEE, Fault & Reject Benchmark Comparison

- Illuminate™ Remote Connectivity (Encrypted Security)

- Diagnostic Analysis Quarterly

Operational Visibility

Illuminate™ Manufacturing Intelligence brings to light your Overall Equipment Effectiveness (OEE) through comprehensive and data-driven drill-down charts, graphics and reporting functionality; delivering superior operational performance capabilities. With Illuminate™ visual devices, such as the Illuminate™ Debug Camera Kit, Embedded Touch Screen Monitor, and Overhead Display, operators will have real time data always within sight, and at their fingertips, to pinpoint production issues and events, and make informed and timely OEE performance decisions.

- OEE Dashboard

- Production, State, Fault, Reject Reports

- Fault Analysis Report

- Live Stream

- Line Clearance

- Illuminate™ Debug Camera Kit

- Operator-assist Guide Lights

- Overhead Display

- HMI Enhancements

- Embedded Touch Screen Monitor

- Mobile HMI Rugged Tablet & Docking Station

Operation Communication

Learn – share – apply exponentially across all systems and lines regardless of location or personnel. Illuminate™ Manufacturing Intelligence greatly increases performance improvement and production sustainability by real time issues and event knowledge sharing and rapid application for total systems notification, reporting, learning, and traceability.

- Operator-to-Operator

- Automated Email Notification

- Automated SMS Notification

- Dashboard and Report Generation

- Multi-language Support

Production and Quality Improvement

Illuminate™ Manufacturing Intelligence gives operators visibility and insight into key production metrics, specific equipment measurement data, and traceability of the entire part process. Combined with Illuminate’s maintenance management functionality, customers can drive continual production performance and quality control improvements with confidence.

- SPC Part Tracking with Analysis (Birth Record)

- Calibration / Event Log

- Recipe Management

- Manual Station

- AIV Product Routing and Monitoring

- Diagnostics Analytics Quarterly

Performance Sustainability

IMI delivers a proactive and cost-effective approach to equipment reliability by achieving predictable and sustainable manufacturing results. A data foundation for informed decision-making and transformational intelligent manufacturing, Illuminate™ helps optimize operations and drive continuous and sustainable performance improvements to lower the cost of goods sold.

-

Production Odometer & Maintenance Management

-

Predictive Maintenance

-

JIT Spares Shopping

40+

years of experience

24,000+

challenging projects

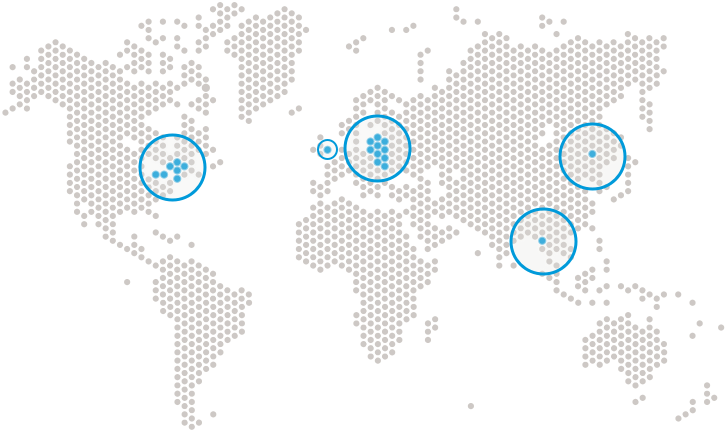

24

global facilities

Realize efficiencies regardless of your industry

The Illuminate™ solution can improve the factory workflow of virtually any manufacturing operation.

Life Science

Illuminate™ Manufacturing Intelligence has been chosen by the world’s leading medical device, pharmaceutical and biotechnology companies for their production lines.

Learn More

Transportation

Automotive, powertrain and aerospace customers look to Illuminate™ Manufacturing Intelligence for production performance and cost-effective sustainability, for a world on the move.

Learn More

Consumer Products

Illuminate™ Manufacturing Intelligence empowers consumer goods and electronics companies to stay competitive and successfully produce everything from mass-to-order to one-of products.

Learn More

Energy

Through Illuminate™ Manufacturing Intelligence, we power the insights that help energy companies keep the lights on and things moving.

Learn More